- +91 98674 95918

- info@jvpmarine.com

OSA carries out shaft alignment on all types of rotating equipment, including engines, gearboxes, generators, shaft (support) bearings, pump sets, winches and bow thrusters. OSA also measure and correct crankshaft web deflections. Alignment checks whether measurements can be performed during different operational conditions so that thermal growth and hull deformation are recorded. In addition, OSA perform dimensional checks with laser or other optical equipment and measure bending stresses using the wireless strain gauges and jack load technique to calculate bearing load, offset, and gap & sag values in propeller, intermediate and high-speed shafts.

CHALLENGES WE ACCEPT

Over 30 years of experience in marine markets, Fully equipped with a professional team and specialized colleagues who have a degree in ship building and mechanical engineering, ROG is your reliable partner for any ship repairs or overhaul. Whether your vessel is damaged after collision, water ingress or fires: our crew is flexible, fast and always on call for repairs, no matter your location. ROG is available for yard repair, voyage repair and port repair.

ROG provides services (24/7) to the maritime and offshore industry. In the center of the Rotterdam Port we offer lay-by facilities for vessels up to 320 mtr and 9,5 mtr of depth, with heavy lift crane capacity. A large yard area for storage of more than 21,000 sqm with a fully equipped workshop.

Business services

ROG shipyard in Rotterdam is one of the unique qualities that make ROG suited to cater to your every need. With open sea access, Their yard is easily accessible for any size ship: whether that is a marine-, sea-going- or jack-up vessel. From the yard, both Rotterdam city center and the airport are within a 15 minute car ride. Do you need a place for your maintenance crew to stay? ROG will take care of your ship and crew with a large accommodation and the right equipment and knowledge to keep your downtime to a minimum.

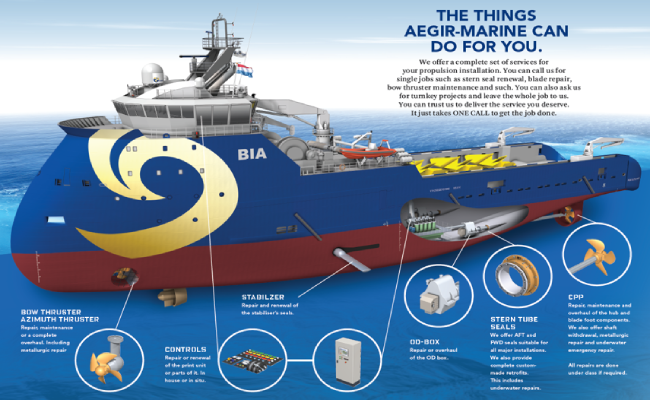

UPE stands for Underwater Propulsion Engineers and that’s precisely what they are. This Rotterdam based diving company is specialized in propulsion repair and maintenance. UPE dives into the pool of sub-marine maintenance professionals .UPE stands for more than 40 years of experience gained by two “whales” in the sector AEGIR Marine BV and Holland Diving International BV.

AEGIR Marine and UPE developed in close cooperation a portable underwater habitat for repairs under sea level. This especially designed Sealdock® is a transportable, lightweight system which can easily be taken along by engineers.

AEGIR-MARINE & UPE OFFER YOU

Atla Propulsion controls provides parts and service for past & current and future propulsion control systems. They keeps stock of spare parts for current and older systems. Their stock consists of all wear items as well as a large selection of logic components. Atla aim to provide a suitable solution for all budgets, therefore Alta offer new as well as refurbished parts. Contact us for price and availability.

As it is Atla believe that a system is only in need of an update when the owner needs more than the system can offer. But new spare parts are getting increasingly scarce; it is therefore we introduced our refurbishment department. Atla also offer a No cure, No pay solution on hardware repair for propulsion systems. This means that all send-in components are inspected free of charge and when possible an offer is made for the repair. It is up to you as a customer if this repair is worth it. Once repaired company offer a 12 month warranty on all repairs.

Value Maritime has developed the Filtree System for small and medium-sized ships based on new unique technology that, in addition to sulphur, also filters ultra-fine particulates and CO2 from the air. It consists of two elements. First of all, a small prefabricated, pre-installed, “plug and play” gas cleaning system in a road transportable housing. This system filters the sulphur, 99% of the particulate matter (fine dust) and CO₂ from the exhaust gases of ships. Secondly, the Filtree system is equipped with a filter that cleans the washing water. Oil residues and particulate matter are removed from the washing water and fed to the sludge tank. The system ensures that the PH value of the used washing water is neutralised and, in combination with a lower CO2 emission, contributes to reducing the acidification of the seawater. We are proud that our Filtree system cleans both air and water!

Because the Filtree System removes sulfur from the exhaust gas flow, ship operators can continue to use the existing high-sulphur fuel instead of the more expensive low-sulphur fuel. The use of this existing fuel therefore saves fuel costs and has a positive effect on the maintenance and performance of the engine. The system ensures compliance with the IMO 0.1% sulphur cap (SECA).

Besides sulphur, the Filtree System also captures CO₂ from the vessels exhaust, preparing your vessel for future regulations on CO₂ and decreasing your vessel’s CO2 footprint

Value Maritime Filtree System is available in eight sizes, suitable for ships with different engine sizes from 3.0 MW up to 15.0 MW.

A non pretium litora adipiscing velit. Felis amet per eros platea ullamcorper a.